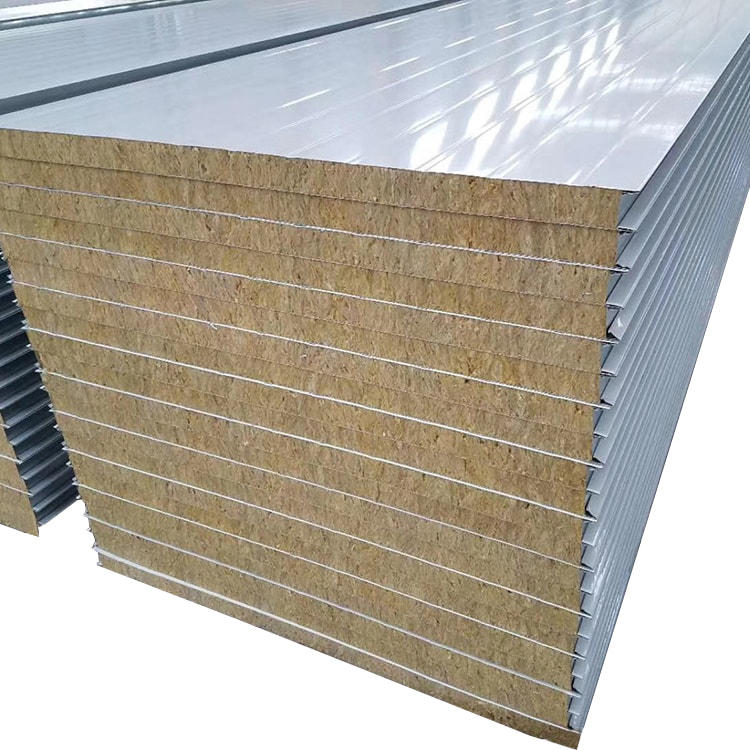

During the design and construction process, it is crucial to ensure the sealing and waterproof performance of Rockwool Sandwich Panel. Here are some recommended steps and considerations:

material selection:

Choose high quality Rockwool Sandwich Panels, ensuring they comply with relevant building standards and regulations.

Choose sealants, waterproofing membranes and other related materials with excellent waterproofing properties.

Design considerations:

During the design stage, the building's geographical location, climatic conditions and usage requirements are fully considered to determine appropriate waterproofing and sealing measures.

Design a proper drainage system to prevent moisture from accumulating around the panels.

For seams and connections that need to be sealed, use appropriate sealing designs, such as sealing strips, waterproof tape, etc.

Construction preparation:

Before construction, ensure that the construction site is dry, clean, and clear of all impurities and obstacles that may affect the quality of construction.

Inspect all materials and tools to ensure they meet design requirements and are in good condition.

construction process:

Construction shall be carried out in strict accordance with the construction drawings and specifications to ensure that the installation position, angle and spacing of the panels meet the requirements.

Install a waterproofing membrane or waterproofing coating before installing the panels to provide extra protection against water.

Use appropriate sealing materials on seams and connections to ensure a tight, gap-free seal. When applying sealant, make sure it is applied evenly and without any omissions.

For parts that require special treatment (such as doors, windows, corners, etc.), use special waterproofing and sealing measures.

During the construction process, avoid damaging the panels and waterproof layer. If it is accidentally damaged, it should be repaired in time.

quality inspection:

During and after construction, quality checks are carried out to ensure that all panels and joints are properly sealed and waterproof.

Use hydrostatic testing or other appropriate testing methods to inspect the waterproofing layer to ensure there are no leaks.

maintenance:

During use, regularly check the condition of the panels and waterproofing layer to detect and repair any damage or leakage in a timely manner.

Avoid placing heavy objects on the panel or performing other operations that may damage the waterproofing layer.

Clean and maintain the drainage system regularly to ensure it is clear and clear.

By following the above steps and considerations, you can ensure that the sealing and waterproof performance of Rockwool Sandwich Panel is effectively guaranteed. This will help improve the overall performance and longevity of the building.