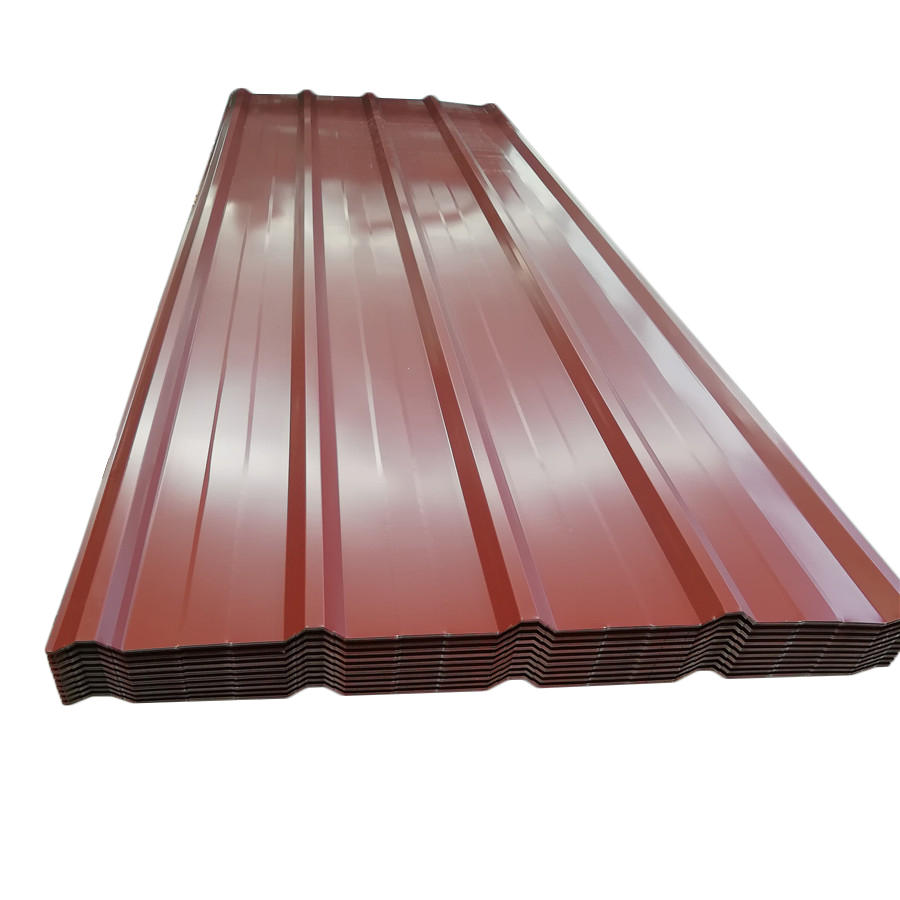

The thickness of Single Corrugated Panel ranges from 0.12mm to 0.80mm. This design range is designed to meet different application scenarios and performance needs. Single Corrugated Panels of different thicknesses show a significant impact on strength and durability. The following is a detailed analysis of this impact:

First, when it comes to strength, thickness is one of the key factors in Single Corrugated Panel performance. Thinner sheets, such as those in the 0.12mm to 0.30mm range, are typically used in applications that are weight-sensitive and require less stringent structural strength, such as temporary buildings or interior partitions. Their lightweight nature makes them easier to install and transport, but they are less resistant to bending and pressure.

The medium thickness Single Corrugated Panel, approximately between 0.31mm and 0.50mm, is the most common choice on the market. Boards of this thickness find a balance between strength and weight, making them widely used in a variety of construction and packaging scenarios. They can provide sufficient support to ensure the stability of the structure without being too heavy and adding unnecessary cost.

For scenes that need to withstand heavy pressure or are used frequently, such as warehouse shelves, outdoor billboards, etc., thicker Single Corrugated Panels, ranging from 0.51mm to 0.80mm, are a more ideal choice. These boards have high strength and impact resistance, and can effectively resist external physical impact and environmental factors.

However, it is worth noting that the strength and durability of a Single Corrugated Panel does not depend solely on thickness. Factors such as the type and quality of the coating, the quality of the raw materials and the sophistication of the production process are equally important. High-quality coating can enhance the anti-corrosion performance of the board and extend its service life; while high-quality raw materials and fine production processes can ensure product stability and consistency.

Therefore, when choosing a Single Corrugated Panel, we need to consider multiple factors, including thickness, coating, raw materials and production processes. Only in this way can we ensure that the selected products can meet the needs of specific application scenarios and have sufficient strength and durability.

In summary, the thickness of a Single Corrugated Panel has a significant impact on its strength and durability. By choosing the right thickness and taking other factors into consideration, we can ensure optimal performance and longevity of the product.